Need help?

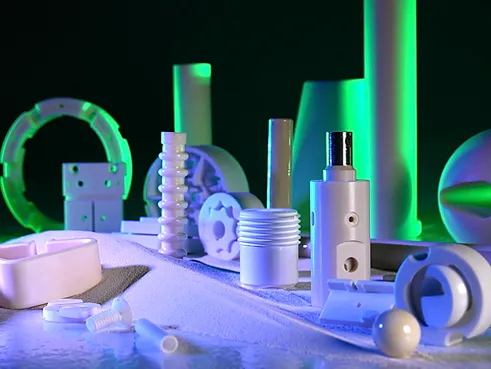

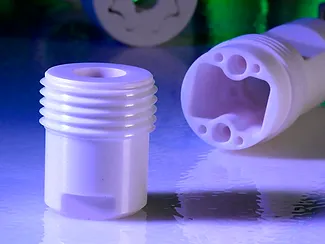

Are you having issues with your current parts with WEAR, CHEMICAL EXPOSURE OR HIGH HEAT? or is your new design requiring attributes you can’t achieve with metal?

At International Ceramic Engineering, we have years of experience, we have seen it all. We invite you into a thought exchange to see how ceramics or advanced plastics can change or enhance your parts which will change the way your product performs. A thought exchange allows you to ask questions and learn about materials and methods that maybe you never thought of, all under NDA. This is NOT a sales call its talking to the experts who can give your project the right guidance to make you a hero on your product team.

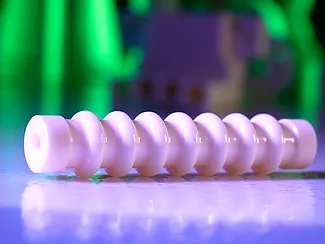

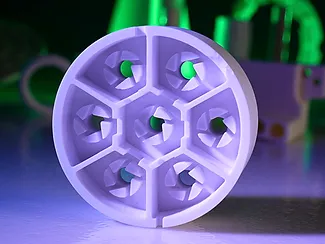

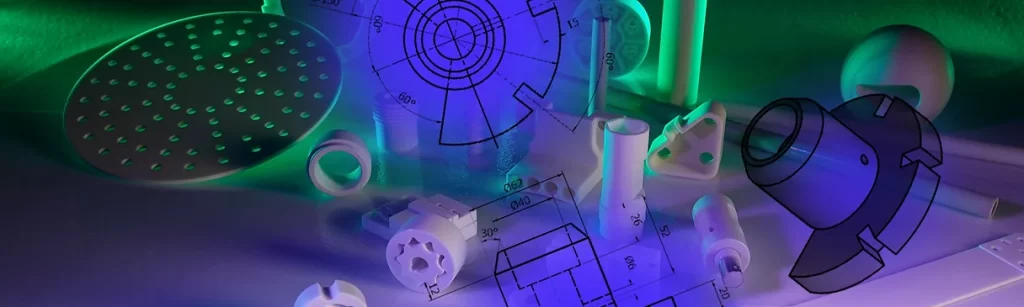

The various technical ceramic types we work with all have unique properties and each will have a best fit for your application. so don’t go at this process alone.

Technical Ceramics

- Alumina Oxide

- 96% Alumina Oxide

- 99.5% Alumina Oxide

- 99.8% Alumina Oxide

- Boron Nitride Ceramics

- HBN Boron Nitride

- HBR Boron Nitride

- HBC Boron Nitride

- HBT Boron Nitride

- Pyrolytic Boron Nitride

- Zirconia Oxide

- Magnesia Stabilized Zirconia

- Yittria Stabilized Zirconia

- Zirconia Toughened Alumina

- Boron Carbide

- Lava

- Macor Machinable Glass

- Silicon Nitride

- Aluminum Nitride

- Steatite, Mullite

- Glass

- Quartz

- Sapphire

Engineered Plastics

- Delrin Plastics

- G10 Plastics

- Nylon Unfilled Plastics

- PEEK Plastics

- Polycarbonate Plastics

- Teflon PTFE Unfilled Plastics

- Torlon 4203 Plastics

- Torlon 4301 Plastics

- Ultem 1000 Plastics

- Vespel SP-1 Plastics

Starting with a thought exchange allows us to create and deliver high-quality, high-precision parts in custom geometries to meet your expectations because you have a better understanding of the process and outcome.

Start now by CALLING 800-779-3321