Rapid Prototyping of Ceramics & Performance Plastics

“Ceramic Prototypes”

International Ceramic Engineering has a dedicated team of product development specialists ready to assist you in the material selection, design and manufacture of your Ceramic & Plastic needs. Our staff of experienced experts and technicians will work with you to solve pre-production issues to save you both time and money.

Most new prototype designs can be produced quickly after receipt of a purchase order and approved drawing. Our goal is to make your idea become a completed quality product fast!

We invite you to join our satisfied customers who benefit from our competitive pricing, timely delivery and expertly manufactured advanced ceramics and performance plastics. We also offer reverse-engineering services for your existing components.

From prototype to production quantities, it’s our pleasure to assist you. Please contact us to find out more about our Rapid Prototyping Services.

Starting with a thought exchange allows us to create and deliver high-quality, high-precision parts in custom geometries to meet your expectations because you have a better understanding of the process and outcome.

Start now by CALLING 800-779-3321

Rapid Prototyping of Ceramic Parts

International Ceramic Engineering has a dedicated team of product development specialists ready to assist you in the material selection, design and manufacture of your Ceramic & Plastic needs. Our staff of experienced experts and technicians will work with you to solve pre-production issues to save you both time and money. Most new prototype designs can be produced quickly after receipt of a purchase order and approved drawing. Our goal is to make your idea become a completed quality product fast!

We invite you to join our satisfied customers who benefit from our competitive pricing, timely delivery and expertly manufactured advanced ceramics and performance plastics. We also offer reverse-engineering services for your existing components.

From prototype to production quantities, it’s our pleasure to assist you. Please contact us to find out more about our Rapid Prototyping Services.

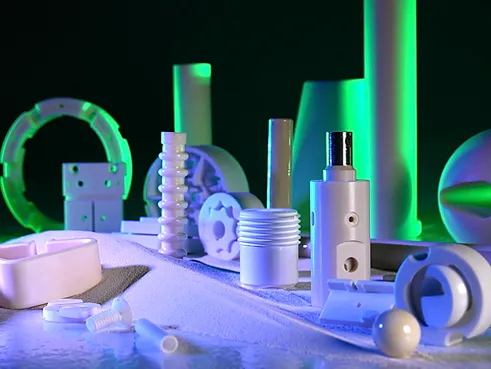

Rapid prototyping (RP) has revolutionized the way industries approach product development, enabling faster, more efficient, and cost-effective creation of complex parts and prototypes. As ceramics play a critical role in various industries, including aerospace, medical, and electronics, mastering the art of rapid prototyping in ceramics holds the promise of significant advancements and innovations.

Ceramics are valued for their unique properties, such as high temperature resistance, electrical insulation, and exceptional hardness. Traditional methods of ceramic manufacturing, however, are often time-consuming, labor-intensive, and inflexible. Rapid prototyping technologies offer a transformative solution by enabling the production of ceramic parts directly from digital models, significantly reducing lead times and costs.

Advantages of Rapid Prototyping Ceramic Parts

1. Speed and Efficiency

Rapid prototyping drastically reduces the time required to produce ceramic parts, enabling quicker iterations and faster time-to-market.

2. Design Flexibility

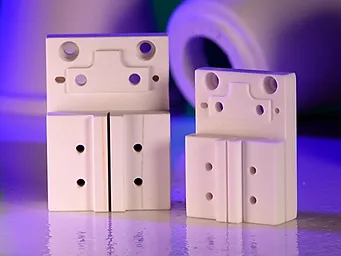

RP technologies allow for the creation of complex geometries and intricate designs that are difficult or impossible to achieve with traditional methods.

3. Cost-Effectiveness

By minimizing material waste and reducing the need for extensive tooling, RP can lower overall production costs, especially for small batches and prototypes.

4. Customization

Rapid prototyping facilitates the production of customized ceramic parts tailored to specific requirements, enhancing their functionality and performance.

Materials Used in Ceramic Prototypes

- Alumina (Aluminum Oxide)

- High hardness

- Excellent thermal stability

- Electrical insulation properties

- Zirconia (Zirconium Dioxide)

- High fracture toughness

- Thermal insulation

- Wear resistance

- Silicon Carbide

- High thermal conductivity

- Wear resistance

- Low thermal expansion

- Silicon Nitride

- High strength and toughness

- Thermal shock resistance

- Good wear resistance

- Titanium Dioxide

- High refractive index

- UV resistance

- Electrical insulation

- Hydroxyapatite

- Biocompatibility

- Used in medical implants

- Bone tissue engineering

- Magnesium Oxide

- High melting point

- Electrical insulation

- Thermal conductivity

- Aluminum Nitride

- High thermal conductivity

- Electrical insulation

- Corrosion resistance

- Lithium Disilicate

- Used in dental applications

- High strength

- Aesthetic properties

- Cordierite

- Low thermal expansion

- Thermal shock resistance

- Used in kiln furniture and catalytic converters

- Spinel

- High hardness

- Transparent to infrared

- Used in optical applications

- Calcium Phosphate

- Biocompatibility

- Used in bone grafts

- Osteoconductivity

- Boron Nitride

- High thermal conductivity

- Electrical insulation

- Lubricating properties

- Yttria-Stabilized Zirconia (YSZ)

- Enhanced mechanical properties

- Thermal barrier coatings

- Ionic conductivity for fuel cells